How to flatten warped wood table top? A warped table top can be a frustrating issue for furniture owners. Whether it’s due to changes in humidity, improper storage, or low-quality materials, a warped table top can affect both the aesthetics and functionality of the piece.

Fortunately, there are effective methods to flatten a warped wood table top and restore it to its original form.

This guide will take you through a step-by-step process of how to flatten warped wood table top, providing you with the knowledge and techniques to successfully address this problem and prolong the life of your beloved furniture.

Understanding the causes of warping

Before diving into the solutions of how to flatten warped wood table top, it’s essential to understand the underlying causes of warped wooden table top.

Wood is a natural material that responds to changes in temperature and humidity.

Exposure to moisture can cause the wood fibers to expand, while dry conditions can lead to contraction.

These fluctuations result in warping, where the wood bends, twists, or bows on the wood furniture. Additionally, uneven finishing or inadequate drying during the manufacturing process can contribute to warping issues.

Preliminary steps

Assess the severity. Start by evaluating the extent of the warp. Minor warping might be manageable with simple fixes, while severe cases might require more extensive intervention.

Identify wood type. Different wood species have varying degrees of susceptibility to warping. Understanding your table top’s wood type can guide your approach to flattening a warped table top.

Gather tools and materials. You’ll need clamps or wood filler, a chemical wood stripper (if you want to get rid of the old paint), wood glue, coarse grit sandpaper, a moisture meter, a heat gun, a hammer and wood chisel and a flat surface to work on.

How to flatten warped wood table top

- Remove the hardware. If your tabletop has any hardware, such as screws or brackets, remove them before proceeding.

- Apply moisture. For minor warping, you can gently apply moisture to the concave side of the warp using a wet towel. The wood fibers will absorb moisture and expand, helping to correct the warp.

- Weighted rest. Place weights or heavy objects on the concave side of the warp and let it sit for several days. This method capitalizes on the natural moisture in the air.

- Heat treatment. Using a heat gun, carefully apply heat to the convex side of the warp. As the wood heats up, it becomes more pliable. Apply pressure to flatten the wood as it cools down.

- Moisture and heat combo. Combine the above methods by applying wet towels to one side and heat to the other, carefully encouraging the wood to flatten the warped wood table top.

- Wood moisturizing. For severe warping, consider moisturizing the entire wood table top. Wrap the table in plastic and introduce moisture evenly to all parts of the wood, helping it regain its original shape.

Sanding and planing techniques

- Sanding. Use coarse grit sandpaper to gently sand the convex side of the warp. Gradually decrease the grit as you progress. This method removes wood material, allowing the fibers to relax and the warp to reduce.

- Planing. A more aggressive approach involves planing the damaged area of the warped table top.

- Use a hand plane or electric planer to carefully shave off layers of wood until the surface of the warped table top becomes even.

- Gradual shaping. Focus on removing wood gradually from the high points of the warp until you achieve a flat surface of the warped table top. Avoid over-planing, as it can lead to an uneven table top.

Using wood filler for minor warps

Begin by identifying the concave side of the warped tabletop. Apply wood filler to this side, making sure to follow the manufacturer’s instructions. The filler will help fill in the gap created by the warp, allowing for a smoother surface once dry.

After applying the wood putty, use sandpaper to gently smooth the filled area.

Start with a coarser grit and gradually move to finer grits for a polished finish.

This method can work well for slight warps and is particularly effective for tabletops with intricate designs where sanding alone might not be sufficient.

Utilizing hand screw clamps for precise correction

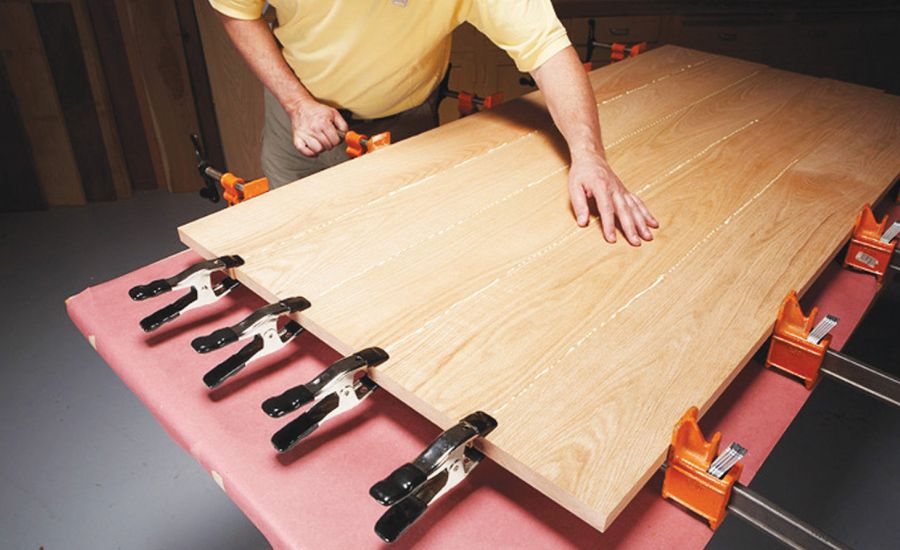

Clamps for hand screws are versatile tools that can be invaluable when it comes to correcting warped tabletops. They provide even pressure distribution, allowing you to gently coax the wood back into its original form.

Start by identifying the concave side of the warp and placing the clamps strategically along the warped area. Gently tighten the hand screw clamps, applying consistent pressure to the warped wood.

Keep a close eye on the progress, adjusting the clamps as needed to ensure that the wood is gradually being guided back to its flat state. Remember that patience is key – rushing this process can lead to further damage.

Ensuring a strong glue connection

When correcting warped tabletops, using wood adhesive is a common method to encourage the wood to regain its original shape. However, achieving a strong glue connection is crucial for long-term success.

Clean the surfaces that need to be glued and ensure they are free from debris, dust, or old adhesive residue. Apply an even layer of wood adhesive to the areas where the wood will be bonded together.

Secure the pieces using the clamps for the hand screw, ensuring that the glue is distributed evenly. Leave the clamps in place until the glue has fully dried and cured, as per the manufacturer’s recommendations.

Collaborating with table supports and glue connection

If the warping issue is interconnected with the table supports, a comprehensive approach is required.

Address both the tabletop warp and any potential instability caused by misaligned or loose table supports. Start by correcting the tabletop using the techniques mentioned earlier.

Once the tabletop is flattened, assess the condition of the table supports. Tighten any loose screws, brackets, or connections.

If necessary, re-glue any compromised glue bonds between the legs and the tabletop. Ensuring a stable foundation will help prevent upcoming warping issues and maintain the integrity of the restored tabletop.

Moisture content adjustment

Measure moisture content. Use a moisture meter to determine the current moisture content of the wood. Ideally, the wood should have an equilibrium moisture content (EMC) that matches the local climate.

Gradual drying or moistening. If the wood is too dry, gradually increase its moisture content by placing a damp cloth over the concave side of the warp. For overly moist wood, allow it to dry slowly in a controlled environment.

Using woodworking clamps and glue

- Apply wood glue. For minor warps, apply glue for the wood to the concave side of the warp. Use clamps to press the wood together until the glue dries. This technique can help to straighten out minor bends in your warped table top.

- Even pressure distribution. Ensure that the clamps distribute pressure evenly across the warped area to avoid creating new pressure points in your warped tabletop.

Addressing warping around table legs

Warping around the areas near the table supports can be a bit more challenging to address. In such cases, you need to ensure that the table supports are properly aligned with the table’s top surface.

If the warping is causing uneven contact between the legs and the tabletop, it might result in wobbling or instability.

To correct this, start by applying the appropriate corrective technique to the warped tabletop itself. Once you’ve successfully addressed the warp, reattach the table supports securely.

Make sure the glue bond between the legs and the tabletop is strong and secure to prevent any future warping issues due to instability.

Reassembly and finishing

- Reattach hardware. Once the warp is corrected, reattach any hardware that was removed earlier.

- Sanding and smoothing. Sand the entire tabletop to achieve a smooth and even surface. Start with coarse grit and gradually move to finer grits for a polished finish.

- Finish application. Apply an appropriate wood finish, such as varnish or polyurethane, to protect the tabletop and enhance its appearance.

Preventive measures

- Humidity control. Maintain a stable humidity level in the room to minimize the problem of a warped table top in the future. Use a humidifier or dehumidifier as needed.

- Proper storage. When not in use, store the entire table in an environment with consistent humidity and temperature to prevent future warping.

- Avoid direct sunlight. Prolonged exposure to direct sunlight can cause uneven drying and contribute to further warping. Position the table away from the windows.

- Regular maintenance. Periodically inspect the table top for signs of warping and address any issues promptly.

Seeking professional help

When you face complex cases like if the warp is extensive or the table top is severely damaged, consider seeking assistance from a professional woodworker. They have the expertise and tools to tackle challenging repairs.

Troubleshooting common issues

Uneven planing. If your planing efforts result in an uneven surface, reevaluate your technique. Ensure the planer’s blades are sharp, and the pressure is consistent.

Excessive sanding. Over-sanding can weaken the wood and lead to an uneven table top. Monitor the progress and avoid excessive force.

Glue residue. If excess glue is visible after clamping, gently scrape it off once it’s dry. Sand lightly to create a seamless surface.

Safety precautions

Protective gear. Wear safety glasses and a dust mask to protect your eyes and lungs from dust and wood particles when restoring your warped table top.

Heat gun caution. When using a heat gun, maintain a safe distance from the wood to prevent scorching or igniting it.

Proper ventilation. Work in a well-ventilated area when working with a warped table top to avoid inhaling fumes from glue or finishes.

Environmental considerations

Sustainability. As you work with wood, consider the environmental impact.

Opt for eco-friendly finishes and proper disposal of waste materials.

Upcycling. If you encounter a warp that’s challenging to fix, consider repurposing the wood for other projects to minimize waste.

Case studies

Case study 1: salvaging an antique table top. Explore a real-life example of restoring a valuable antique table top with severe warping issues.

Case study 2: a DIY success story. Read about a DIY enthusiast’s journey in flattening a warped table top using innovative techniques.

Expert insights

Woodworker’s perspective. Gain insights from an experienced woodworker on the intricacies of correcting wood warping and the joys of craftsmanship.

Restoration specialist interview. An interview with a furniture restoration specialist reveals professional tips for addressing challenging cases of warping.

Frequently asked questions

As you embark on this journey to flatten your warped tabletop, take your time, and don’t rush the process. Each step plays a crucial role in achieving the desired outcome.

If you have any questions left about warped tabletop, here are the answers for them.

How do you flatten a wood table top?

To flatten a warped wood table top, you can use methods like applying moisture to the concave side, using weights, applying heat treatment, sanding, planing, or using woodworking clamps and glue to correct the warp.

The specific method depends on the severity of the warp and the tools available.

Can warped wood be made straight again?

Yes, warped wood can be made straight again using various techniques. Methods like applying moisture, heat treatment, sanding, planing, and using clamps and glue can help correct the warp and restore the wood to its original shape.

How do you straighten a cupped table top?

To straighten a cupped table top, you can start by applying moisture to the concave side, then use weights or clamps to gently encourage the wood to flatten out.

Applying heat to the convex side while applying pressure can also help. Gradual sanding and planing techniques can be employed for more severe cases of cupping.

Conclusion

Exploring the question about how to flatten warped wood table top is a gratifying endeavor that combines problem-solving, craftsmanship, and creativity. By choosing the right technique based on the severity of the warp, taking precautionary measures, and embracing the learning process, you can successfully restore your table top to its former glory.

Remember that each piece of wood has its unique characteristics, and as you work with it, you’re not just repairing furniture – you’re connecting with the natural world and preserving its beauty for generations to come. Flattening a warped wood table top requires patience, attention to detail, and the right techniques.

By understanding the causes of warping and choosing the appropriate method for your situation, you can successfully restore your warped table top to its original beauty. Remember that prevention is key; maintaining proper humidity levels and avoiding extreme conditions can go a long way in preserving the integrity of your wood furniture.

With the knowledge gained from this guide, you’re equipped to rescue your beloved piece of furniture and enjoy its functional and aesthetic value for years to come.